Warehouse Solutions

Streamlining Warehouse Solutions for Smarter Logistics

Warehouse Solutions

Warehousing innovation is at the forefront of all industry leaders' priorities, focusing on the safety and efficacy of timely supplying customers.

The technology we support includes but is not limited to include: warehouse automation, material handling, warehouse protection, and loading bay solutions.

We acknowledge and have a like-minded understanding of how critical it is to meet the customer's needs. Therefore, we work with technology OEMs and logistic centre designers on projects to reduce maintenance needs, minimise downtime, extend the lifecycle of machinery and equipment and increase safety.

Industry Solutions

Expert technical support in design and material selection processes, tailored to your warehouse automation needs.

Warehouse Automation Applications

Warehouse Protection Applications

Material Handling Applications

Problems we solve

- Warehouse Solutions

Case Study: Enhancing Application Performance

Area of focus: Docking / Loading Bays

Industry: Warehouse Solutions

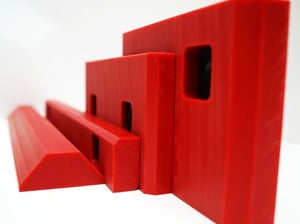

Nylacast Solution: Nylacast Buffalo Dock Bumpers

Challenge:

Progressive wear and insufficient support, coupled with harm to external structures and docks, result in continual maintenance expenses.

Solution:

A thermoplastic docking system leading innovation in HGV docking. A design that provides safeguarding for loading bays, vehicles, and yard floors, preventing damage to buildings and docks. This leads to decreased ongoing maintenance costs and improves docking performance at warehousing and distribution facilities.

Advantages:

- Low maintenance and decreased downtime

- Corrosion resistant

- Safety and high visibility

Contact Our Experts