Food

Engineering Polymers: The Secret Ingredient in Food Manufacturing Excellence

Building Trust and Confidence in Food Production with Nylacast

The food manufacturing industry encounters diverse challenges that impact its operations, sustainability, and expansion. These challenges encompass escalating costs, dynamic consumer preferences, concerns about food safety, and considerations regarding environmental impact.

Nylacast addresses these needs by providing robust support to food processing facilities transporting raw materials and finished products throughout the production line.

Engineering Polymers are selected for application in food manufacturing equipment as they are versatile and adaptable, with a vast range of polymers available with FDA approval. Our clients rely on us to advise on the best Polymers to enhance operational efficiencies, reduce the necessity for maintenance and downtime, and prioritise the safety of consumer food products.

Industry Solutions

Our comprehensive technical support in design and material selection processes further emphasises our commitment to the industry.

Our material technology prevents material sticking to overcome friction from an applied force

Applications

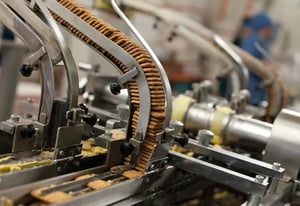

- Bakery Drums

Case Study: Enhancing application performance

Equipment: Bakery Dough Dividers

Industry: Food Industry

Original Material: Stainless Steel

New Material: Nylacast FDA Approved Molding drum

Challenge:

Corrosion and rust lead to product contamination and pose potential health risks.

Deploying a non-stick, low weight, easier handling, whilst delivering a certified food grade approved solution capable of meeting production demands.

Solution:

FDA-approved, lightweight polymer mold drum, with a design that prioritizes easy cleaning whilst guaranteeing the production of a consistent and uniformed dough ball.

The polymer drum is durable and corrosion-resistant, preventing product contamination and contributing to a high-quality production system.

Advantages:

- 1 piece design eliminates flex or distortion

- Low maintenance and decreased machine downtime

- Corrosion resistant

- Available in multiple size variants

Contact Our Experts