Wear Pad

Machine Engineered Polymer Solutions with safety and efficiency in mind.

What is a Wear Pad?

A Wear Pad is a component designed to reduce friction and wear between moving metal parts in industrial machinery. Wear pads are typically positioned within the boom section of machine groups, such as aerial work platforms, telehandlers, backhoe loaders and mobile cranes to name a few.

Wear pads are predominately manufactured in Engineered Polymers as they improve wear rate in the boom through a decreased coefficient of friction between metal parts, increased guide and load handling, high compressive strength, improved safety of the operator and greatly reduced maintenance and down time of the machine, all while reducing the input force required to overcome system friction.

Why Choose Polymer Wear Pads?

Engineered Polymers are the material of choice as they reduce or eliminate industry challenges, such as:

Application uses in Industry

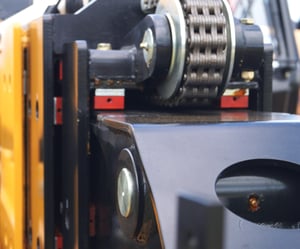

Examples of Wear Pads in use:

- Support allows thermal expansion and contraction while protecting painted surfaces.

- Crane booms sliding pads reducing wear on the boom structure.

- Bridge bearings accommodating movement and reducing wear.

- Conveyor systems that guide and support moving parts with minimal wear.

Industry technology that makes use of Wear Pads includes:

- Telehandler

- Mobile Cranes

- Backhoe Loader

- Aerial Work Platforms

- Straddle Carriers

- Forklift

Enhanced Performance Material

Contact Our Experts

Talk To The Team.

Speak to one of our experts about creating the right solution for your application.We are always happy to help.