Crane & Lifting Solutions

Taking your crane and material handling operations to new heights

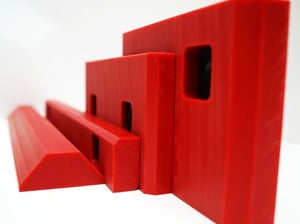

Unleash the potential of polymers for your lifting equipment

Safe operations, high load handling and stability whilst operational in demanding environments is at the forefront of Nylacast design and consultancy offering to our partners when supporting with material handling equipment

Our goal is to increase equipment performance and reliability, reduce maintenance needs and optimise safety.

Industry Solutions

Drawing on our technical expertise, we provide comprehensive support in design and material selection processes, aimed at improving crane performance, safety and minimising maintenance downtime.

Applications

Problems we solve

- Sheave Wheels

Case Study: Enhancing Application Performance

Equipment: Port Side Gantry Crane

Industry: Crane and Lifting

Original Material: Steel

New Material: Nylacast Polyamide Sheave

Challenge:

Wear and Abrasion:

- Cause: Interaction between stainless steel wires and metal sheaves.

- Effect: Compromises the integrity of the wire rope, reducing its strength and overall performance.

Corrosion:

- Cause: Interactions with different metals in the sheaves leads to erosion.

- Effect: Corrosion weakens the wire rope and reduces its lifespan.

Lubrication:

- Cause: Inadequate or improper lubrication between the wire rope and the sheaves.

- Effect: increase in friction and wear, contributing to premature failure.

Solution:

Reduced Wear and Abrasion:

- Solution: Polyamide sheaves with a smoother surface, reducing friction and wear on the stainless steel wire ropes.

- Effect: Protects the wire rope from abrasion, extending its lifespan.

Corrosion Resistance:

- Solution: Polymer sheave to act as a barrier against galvanic corrosion.

- Effect: Isolating the stainless steel from direct contact with other metals, the polymer enhances corrosion resistance and protects the integrity of the wire rope.

Lubrication Enhancement:

- Solution: Self-lubricating material properties formulated with lubricating additives, eliminating the need to manually grease the system.

- Effect: Improved lubrication reduces friction, minimizing wear and extending the life of the wire rope.

Advantages:

- Increased rope life

- Reduced Maintenance and Downtime

- Reduced Component Weight

- Self-lubricated

- Cost Effective in comparison to steel